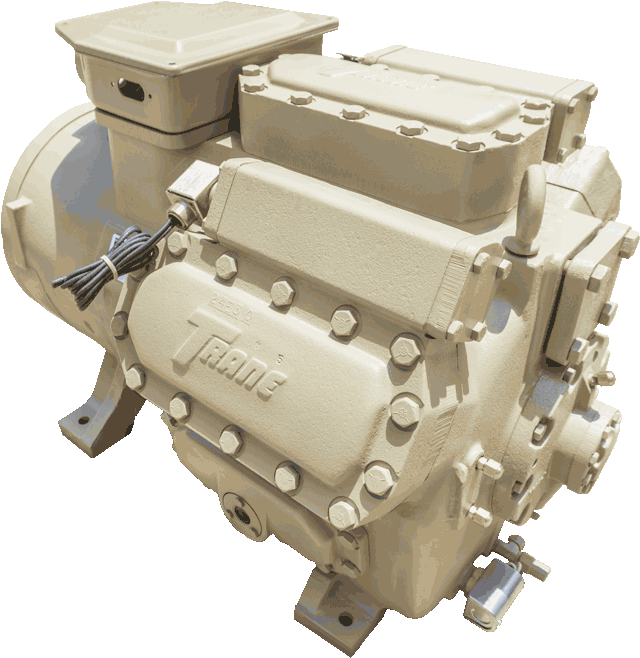

Rebuilt Trane Compressors

Recently I had a request via email and it went like this.

Hi Ron, checking to see if you have access to a compressor for an old-old 100 ton Trane chiller. This is an R-22 with mineral oil. Hoping you can help. (pics of the chiller were attached)

My response went like this.

Client name,

I recently quoted a rebuilt similar for another project with the cost of $**** with a 4 to 5 day lead time. Allow for shipping cost of about $300 bucks and we would need the old core back.

I would have to confirm the model of the compressor that you have so I would need that information off of the compressor and recheck lead times.

Clients response.

Ron. What is the typical warranty on a rebuild?

My response.

1 year the same as a new remanufactured compressors.

Over the years I have personally installed both rebuilt and remanufactured reciprocating compressors and the debate is which is a better option and in my opinion is it depends on what is available and costs.

Basically a rebuilt compressor is torn-down and all the pistons, crankshafts, cylinder walls, etc…. are checked with calipers to see if they are within manufactures specifications and reuse the parts if good. If the parts are out of tolerances used parts from other compressors and or brand new parts will be used to complete the rebuild.

Where as a remanufactured compressor are torn down and supplied with all new parts. Both come with a 1 year warranty.

I ended up selling the Trane 50 ton rebuilt compressor so shoot me an email if you need a rebuilt Trane, Carrier, or York compressor.

Enjoy and stay tuned.

Ron